If you are thinking of building a deck or repairing one, chances are you probably like your house to be a little neat and fancy.

After all, having a deck is often a fun and relaxing way to have your morning coffee or spend a weekend afternoon. But to have that luxury, you need to build and maintain your deck in the right way.

We all have our unique pick when it comes to choosing materials for installing a deck. Some prefer natural wood while others prioritize composite or pressure treated wood.

Whatever your choice may be, this guide provides quick yet effective know-how into the matter. It'll help you to pick the best deck screws for pressure treated wood or lumber decks as well as decks made from softwood, hardwood, composite wood, etc.

Image | Name | Editor's Rating | Price |

|---|---|---|---|

Eagle Claw Tools and Fasteners, Silver Stainless Steel Deck Screws | 5 out of 5 | ||

SNUG Fasteners, Tan Fence & Deck Screws (Pack of 100) SNG919 | 5 out of 5 | ||

Kreg, Deck Screw (box of 700) SDK-C2W-700 | 4.5 out of 5 | ||

Hillman Fasteners, DeckPlus Tan Deck Screws (Pack of 310) 48419 | 4 out of 5 | ||

Lightning Stainless, Silver Deck Screws (Pack of 100) FBA_ssds8114-100 | 4.5 out of 5 |

Our Recommended Best Deck Screws for Pressure Treated Wood

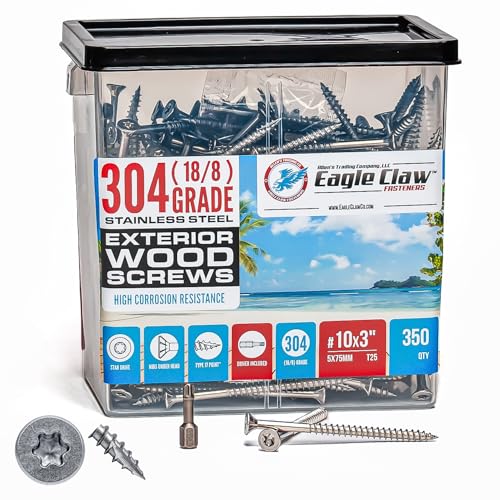

1. Eagle Silver Stainless Steel Deck Screws

This product is manufactured at a level of durability which is appropriate for properly putting together your deck planks.

The package contains 350 pieces of 18-8 grade stainless steel screws. Due to their construction, the screws are particularly recommended by users of pressure.

Each screw has a #10 diameter with a length of 3-inches. It has a flattened head portion, which easily does the job of blending into your deck.

The drive style is a standard Torx (T25) drive, also known as a star drive. Therefore, it’s easy and quick to install. It also doesn’t cause screw-driver slippages during the process.

The head is sloped into the shank of the screw. This helps the screw-head to properly level with the ground while providing ground adherence.

The tip of the screw is a type-17 point tip. That means, it'll cause much fewer debris throw-outs compared to a type-A or type-B tip. Type-17 point tips are also great at reducing splitting issues while putting together planks.

Every screw of this package has an anti-corrosive coating and a nice, burnished look. So, if you own a deck that’s on a coastal area, which constantly deals with rust inducing elements like salt and water, these screws will be a perfect fit.

The package also includes a Torx drive bit for your extended comfort.

Highlighted Features:

- These screws are specially designed to plank together pressure treated wood.

- Each screw comes with an anti-corrosive coating and a burnished polish.

- If you own decks in a wet area, these anti-rust screws will be a proper choice.

- Designed with a T25 drive, they are easy to install and won’t cause cam-outs.

- The product offers an inclusive Torx drive bit for user comfort.

- TYPE 304 (18-8) GRADE 3 INCH STAINLESS STEEL DECK SCREWS for Decking, Fencing and general-purpose...

- RECOMMENDED for use in all COASTAL, WET and OUTDOOR applications, including decks, balustrades, fences,...

- HIGH CORROSION RESISTANCE means no more ugly rust stains on your beautiful outdoor timber structures.

- SUITABLE for use with all HARDWOOD, SOFTWOODS and PRESSURE TREATED lumber, including Redwood and Cedar.

2. SNUG SNG919 Tan Fence & Deck Screws

Snug fasteners bring to market a simple yet effective product with the SNG919.

The package contains 100 pieces of stainless steel (305-grade) screws. These screws provide more adhesion strength and longevity than regular metal screws made of copper or zinc.

They are layered with an anti-corrosive coating to provide environmental flexibility. So, you can use them both as outdoor deck screws and for internal wood-related repairs.

Each screw is 2.5-inches long and has a #9 diameter. It’s designed with a bugle style head, which has a flat top with nibs sloping to meet the shank. This design helps the screw to sit in level with the deck by countersinking it.

The screws are manufactured with a standard T25 drive. Often generalized as a star drive, this drive system makes installation quick and safe by providing a fast torque and preventing cam-outs.

The shanks are partially threaded using a coarse style threading. This means, each screw has fewer threads per inch and the threads are formed larger than the screw’s diameter.

The threads are left-handed instead of right, which can be of great use to some users. The threads of each screw are sharp and self-cutting, which easily drives them into the planks.

The screws also come with a Torx (T25) drive installer bit. So, you won't need to waste time finding the right screwdriver to install them.

They are designed with a type-17 point tip which makes them self-drilling. Thus, you won’t need to make any pre-drilling holes either.

Highlighted Features:

- The product contains 100 pieces of self-drilling screws.

- It comes with a compatible Torx driver bit.

- You won’t need to make pre-drilling holes to install decks using these screws.

- The screws are manufactured with left-handed threading.

- Designed with a bugle style head, the screws camouflage nicely into the deck.

- Premium Corrosion Resistant Ultra-Guard Tan Coating

3. Kreg, Deck Screw (box of 700) SDK-C2W-700

If you're looking for that sweet deal where ample quantity is provided without any compromise in the quality and burning a hole in your pocket, this is the product for you.

The product comes in a high-quality plastic container, equipped with a carrying handle. The container holds 700 stainless steel screws.

These go through a thermochemical heat treating, known as case hardening, for increasing their yield strength. Thus, these screws can provide superior holding strength when it comes to holding deck planks together.

The 2.625-inch long screws have a #8 diameter each. They are also coated with zinc to resist corrosion. This feature can be specifically helpful for installing decks in wet or salty areas. The screws are designed to install up to 2-inch long and 1.5-inch thick deck planks in a durable manner.

Each screw is designed with a flattened head and straightly sloped nibs. So, apart from providing a good amount of ground adhesion, it also manages to reduce the possibility of cracking the planks through installation.

The screws have a square style (KTX) Torx drive. This drive style lessens the spinning of the screw and slippage of the screwdriver, ensuring a quick and smooth installation. It also increases the driving power.

The shank is partially threaded. Its thread-less upper portion makes installing planks across the deck's joist easier and durable.

Each screw is manufactured with coarse style threading with an aggressive cut which will help you to drive them into the wood (specifically hardwood and pressure treated wood) with comfort and precision.

These self-drilling screws are custom made to work with Kreg’s deck jigs. They are colored in a neutral range which helps them to mix in with the deck. Each screw is also protected by a tri-layered patented (“Protec-Kote”) finish to resist corrosion caused by humidity, dampening, etc.

Highlighted Features:

- If you’re using Kreg’s deck jigs, these screws will fit right in.

- They have a trimmed head and neutral coloring to provide better camouflage.

- Equipped with a KTX square drive system to reduce spinning and driver slippage.

- The screws are made using thermochemical heat treatment for durability.

- The shanks are partially smooth to install planks across the deck’s joist easily.

- Premium Deck Screws: These home improvement screws are perfect for building a long-lasting outdoor deck

- Outdoor Screw Assortment: 3-layer coated screws are durable; case-hardened steel prevents bending or...

- Self-Tapping Tip: Wood screws are easy to drive without slipping; compact heads with a flat underside...

- Secure Outdoor Furniture: Smooth upper shanks tightly join deck board and joist; 2 inch length for 4/4...

4. Hillman 48419 Deck Screws (Pack of 310)

If you are concerned about corroded screws ruining your beautiful deck, this product can be your savior. Hillman Fasteners provides you 310 pieces of 305-grade stainless steel screws, which have one of the most advanced anti-corrosive coatings in the market.

The screws have a ceramic-brown colored coating that's consisted of 4 layers. First, they are layered with Zinc, then a second layer of chemicals for adhesion is applied. On top of the 2nd layer, you’ll get an epoxy coating that’s finally covered with a protective finish.

Since pressure treated woods contain a variety of chemicals to protect against erosion or infestation, they can often corrode ordinary deck screws. And if you have such a deck in a wet atmosphere then the chance of rusting and corrosion increases even more.

However, with such an advanced coating, these screws will perform at a superior level as deck screws for treated lumber decks, regardless of the weather. The coating has also passed the “1,000-hour salt spray" testing.

They are delivered in a transparent and reusable container with a user-friendly lid system in place. Each screw is 3-inches long and has a #10 diameter. They are designed with flat heads.

Manufactured with advanced countersinking nibs, the screw-heads meet a reinforced shank. The shank is partially coarse threaded and ends in a self-drilling type-17 point, equipped with a quick start feature.

This way the screws reduce plank splitting and save you the trouble of making any pre-drilling holes.

The screws have a specialized “no-strip star drive” system. Thus, you won’t face stripping, cam-out, or slippage issues. It’ll provide a faster torque and enhanced drive energy for smooth installation.

The manufacturer also provides a compatible (T25) star drive bit with the package.

Highlighted Features:

- These screws have an anti-corrosive coating that’s consisted of 4 layers.

- The coating has passed the “1,000-hour salt spray" testing.

- You’ll get a specialized “no-strip star drive” system with every screw.

- They are made with advanced countersinking nibs and reinforced shanks.

- Each screw has a self-drilling type-17 point, equipped with a quick start feature.

- SELF-DRILLING POINT: Together, coarse screw threads and a self-drilling point design eliminate the need...

- FLAT-HEAD STYLE: Sits flush with material

- TAN CERAMIC COATING: 4-layer coating provides superior rust and corrosion protection

- STAR DRIVE STYLE: Also known as Torx, this drive is designed to reduce slippage and camout when...

5. Lightning Stainless, Silver Deck Screws

In this product, Lightning Stainless offers you deck screws that provide a combination of sturdy build and innovative features in equal amounts.

Each screw is made from 18-8 grade stainless steel. They have a shiny finish and will go well with any silver-toned wooden deck.

These pressure treated wood screws come highly recommended by many users for their ability to perform on this particular wooden platform.

They also have a lasting anti-corrosive coating, making them ideal to use on decks situated near seashores, coastal areas, and places with a heavy rainfall record.

With a #8 diameter and 1.25-inch length dedicated for every screw, this package delivers 100 industry-grade deck screws that'll make installing decks a breeze.

However, they are self-tapping, not self-drilling screws. For this reason, the manufacturer recommends making pre-drill holes where the drill size is 0.10-inch for softwood and 0.12-inch for hardwoods. Though, keep in mind that these are measurements for straight pilot holes.

Being one of the best deck screws for pressure treated wood or lumber made decks, these also sport the standard bugle shaped head to smoothly mix into the decks surface. The head's flat top and sloped nibs allow these screws to stay perfectly level with the ground.

They have #2 Robertson Drive, popularly known as a square drive system. This system allows the user a greater drive force, lesser cam-outs, and stripping, as well as increased torque during installations.

Each screw has a cleverly designed partially threaded shank. The threads are right-handed, so it'll be easy to use for most deck owners. The helix of the threads is designed to layout the exerted force evenly to provide easy installation and stronger holding power.

Every screw has a self-tapping, type-17 (auger) point tip. This lets you install a deck with less effort yet more efficacy.

Highlighted Features:

- With a self-tapping tip, the screws provide an effortless yet effective installation.

- The screws have right-handed threading, making them easy to use.

- The threads even out exerted force for superior driving and holding strength.

- Using #2 Robertson drive, they lessen splitting and increase torque.

- Each screw has a self-tapping tip, which increases its holding power.

- Screw Size #8 (0.164") - Straight Pilot Drill size for Soft Wood 7/64 . Straight Pilot Drill size for...

- Screw length measured from top of flat to tip of screw 1-1/4" (1.25") - Screw head Diameter 0.340"

- #2 Robertson Drive ( Square )

- Made of highly corrosion resistant 18-8 Stainless steel

6. SNUG Fasteners, Tan Fence & Deck Screws (Pack of 100) SNG917

The SNG917 is a smaller version of our previously mentioned Snug Fasteners screws. It has all the perks of the SNG919 but is designed to provide services for a set of different measurements.

Each screw of the pack is 1.625-inches long and has a #8 diameter. For camouflage purposes, they have bugle style heads with sloped, countersinking nibs. The shank is partially threaded.

The threading style is coarse, which is considered standard by most deck installation experts. The threads have an extra sharp cutting edge, which will make driving the screw into the wood easier. It'll also ensure that screw sits tight and firm into the planks, increasing the holding strength of the product.

The threads are also left-handed, meaning it moves closer to the user when turned in a clockwise direction and moves away when turned counterclockwise. This feature may serve well for users who are lefties.

Every screw is designed with a Torx (T20) drive system. Thus, it will provide more driving strength and higher torque as well as reduce splitting, cracking, and cam-out issues. This will help you to easily and safely install your deck.

The screws have a self-tapping, type-17 point tip. Despite not being self-drilling screws, the self-tapping points are sharp enough to not require pre-drilling holes for usage most of the time. This feature also allows the screws to smoothly penetrate pressure treated lumbers.

One of the best wood deck screws on the market, all pieces of this package are made from 305-grade stainless steel with “Ultra-guard” anti-corrosive coating. It also includes a compatible Torx drive bit.

Highlighted Features:

- Each screw is 1.625-inches long and has a #8 diameter.

- Designed with a type-17 point tip to smoothly enter pressure treated lumbers.

- Using a Torx (T20) drive, the screws provide superior driving power and torque.

- The screw threads have a sharp cutting edge to increase the holding strength.

- The T20 drive system reduces splitting, cracking, and cam-out issues.

- Premium Corrosion Resistant Ultra-Guard Tan Coating

7. WoodPro Fasteners, Brown Composite Deck Screws (Pack of 435) CD10X212B-5

Are you looking for deck screws that don’t compromise on any aspect of the tool? Then WoodPro’s CD10X212B-5 won’t disappoint.

The product delivers 435 pieces of stainless steel screws in a transparent and reusable plastic container. Each screw is 2.5-inches long and has a #10 diameter.

The screw-head has a flat top and straight undercuts, which makes the entire portion look rectangular. It's then joined to the shank using self-countersinking nibs.

The shank is double-threaded. Its top portion is a single-thread, sharp-v edged threading and the latter portion is a buttress edged threading. The screw ends in a type-17 point tip. The tip is self-drilling and equipped with a quick start feature.

Each screw is designed with Torx (T-20) drive. The package also includes a compatible and non-slip 25-millimeter Torx drive bit for ease of installation.

The screws are coated with the famous PPG electrocoating, giving them a neutral brown color and anti-corrosive properties. The coating also adds to its quality by passing the "1,000-hour salt spray" test.

Therefore, many professionals consider them as one of the best screws to use for wood decking projects, especially ones that use pressure treated planks like ACQ.

Highlighted Features:

- The screws have PPG electrocoating, which makes them anti-corrosive.

- The product uses a double-threaded shank for increased holding power.

- They are considered to be a top choice for adjoining treated woods like ACQ.

- You’ll get a non-slip, 25-millimeter Torx compatible drive bit with the product.

- The screw-head is flat with straight undercuts and self-countersinking nibs.

- No.10 by 2-1/2-Inch, Includes One 25mm T-20 Star Bit

- T-20 Star Drive, Torx(tm) Compatible

- Sharp Type-17 Point

- PPG Industries 1,000 Hour Brown E-Coat

8. PowerPro, Premium Outdoor Wood and Deck Screws

In this product, PowerPro rolls out 2700 screws equipped with such advanced technologies that justifiably sets a new standard for modern deck screws.

Each screw is made from 1022-grade stainless steel and goes through a heat treatment process for improving its strength. It’s 2.25-inches long and has a #9 diameter.

The screw-head is designed with special nibs. These nibs are equipped with auto-countersinking blades, which allows the screw to sit completely level with the deck, seal its surface, and reduce the rate of splitting by 75-percent compared to regular screws.

The nibs connect the head to a shank, which is designed with the patented “no-split twist” design. The upgraded shank is double-threaded and creates a perfect sized hole every time. It also lessens drive friction, improves the holding power by 15-percent, and provides a 20-percent faster installation.

The screw uses a self-starting, type-17 point tip. The tip is self-drilling and equipped with the manufacturer’s “Bore-fast” technology, which allows the screw to drive into the wood 20-percent quicker than average decking screws.

The screws are equipped with a no-strip, Torx (T-25) drive system. This feature reduces drive force to improve battery life and, thus, can be used easily with automatic Torx compatible drivers. It's also manufactured to reduce cam-out and stripping issues.

The manufacturer uses a nanotechnology-based polymer coating to coat the screws with dual-layer, anti-corrosive coating. The coating uses a bronze layer finished by an epoxy layer to provides state-of-the-art corrosion and rust resistance.

Highlighted Features:

- The screws use a nanotechnology-based polymer coating for rust resistance.

- Each screw uses a self-starting and “Bore-fast” equipped type-17 point tip.

- The innovative shank design improves holding power by 15-percent.

- The product offers a 20-percent faster installation than regular screws.

- The screws reduce splitting by 75-percent compared to other deck screws.

- ENGINEERED FOR THE OUTDOORS: Ideal for decking and any outdoor wood project

- BEST-IN-CLASS CORROSION PROTECTION: Bronze epozy coating offers superior rust and corrosion protection

- SELF-STARTING TIP: Offers 20 percent faster engagement into wood; no splitting

- UNIQUE STAR DRIVE TECHNOLOGY: T25 Drive size virtually eliminates camout for a smooth effortless drive...

Wood Deck Screws Comparison Chart

Image | Name | Diameter | Length | Pieces Per Pack |

|---|---|---|---|---|

| Eagle Claw Tools and Fasteners, B07JNL53WG | #10 | 3-inches | 350 |

| SNUG Fasteners, SNG919 | #9 | 2.5-inches | 100 |

| Kreg, Deck Screw SDK-C2W-700 | #8 | 2.625-inches | 700 |

| Hillman Fasteners, DeckPlus 48419 | #10 | 3-inches | 310 |

| Lightning Stainless, FBA_ssds8114-100 | #8 | 1.25-inches | 100 |

| SNUG Fasteners, SNG917 | #8 | 1.625-inches | 100 |

| WoodPro Fasteners, CD10X212B-5 | #10 | 2.5-inches | 435 |

| PowerPro, 967776 | #9 | 2.25-inches | 2700 |

How To Choose Deck Screws for Pressure Treated Wood?

1. Level Of Camouflage

You must ensure the screws provide a high level of camouflage. Pressure treated wood planks are expensive due to their superior durability. However, if you choose screws that don't match the plank then you'll have an ugly looking deck despite all the expenses.

This issue can occur due to several reasons. For example, if the screw heads aren't level with the ground and stick out. It can also happen due to choosing screws coated/burnished with colors that contrast sharply with the wood planks.

Thus, ensuring that the screws smoothly mix in with the deck after installation should be one of your prime concerns.

2. Drive Type

It's important to choose screws with the proper drive type. This is because from installation to maintenance, the drive type of your deck screws will play an important role.

We recommend choosing modern and technically advance drives for your deck installing screws. For example, the Torx drive is universally known for providing quick installation, preventing cam-outs, and reducing the amount of dust, chips, and other debris.

In terms of maintenance, choosing a drive type with these qualities will help you. It'll allow you to quickly change, wash, or repair planks by providing a fast and reliable screw-out as well as a screw-in method.

3. Style Of The Tip

To provide ease of installation and preserving the structural integrity of your valued wooden planks, the tip of your screws requires a good amount of consideration.

Without the right tip or point, you’ll face difficulty in putting the planks together. A wrong choice in this matter can also split or crack your deck planks.

That’s why you need to ensure that your preferred screws have advanced engineered tips.

We recommend choosing a self-drilling tip as it’ll save you the trouble of making pre-drilling holes. However, you can also go for self-tapping tips, which won’t be as hassle-free as self-drilling tips but can provide more or less the same amount of benefit in avoiding cracking and splitting issues.

Various tips can aid you in this matter. For example, the type-17 point tip is generally held in high regard for deck screws, which is evident from its wide use in the industry.

4. Thread Count, Handedness, And Edge

Choosing screws with threads that are engineered to serve your particular purpose can be tricky.

Some wood planks work well with fine threads and a high thread count (measured by Thread Per Inch or Thread Pitch depending on the measurement system), while others are compatible with coarse threads.

Also, most threads are naturally angled right-handed. However, there are screws with left-handed threads, such as Snug Fasteners' SNG919.

In terms of edge, the best deck screws for pressure treated wood usually come with a sharp and serrated edge. Because, it makes driving the screws into the wood easy and fast, as well as increases their holding power.

5. Merging Amount And Quality

Deck screws are mostly sold in bulks, that is in a packaging that contains anywhere from 100 to 700 pieces. Thus, you can be overwhelmed by the quantity that comes at the cost of quality.

That's why we designed this guide to list products that'll give you the sweet spot between amount and quality.

Don't compromise on quality because this decision will have a larger impact on your deck's overall health. Instead, find the right balance between an economically beneficial amount and the overall quality of the screws.

6. Weather Resistance

A deck is by definition an outdoor installation. So, it’s always a good idea to make sure your deck screws can “weather the storm” so to speak.

That is, purchase deck screws that are equipped with weather-resistant features. We recommend buying high-grade stainless steel (e.g. 304, 305, 306, 18-8, etc.) screws as these will naturally protect against a variety of weather issues, such as corrosion.

Specifically, if you live in a humid area with daily rains or a seaside residence where salt and splashes of water are in regular contact with your deck, using weather-resistant screws will save you multiple repair and replacement costs.

7. Material Compatibility

We all have our unique choice of lumber while building a resident or commercial deck. Some like to use natural wood (e.g. softwood and hardwood), while others may go for a composite or pressure treated lumber deck.

Manufacturers often provide specialized screws for particular wood types. For example, WoodPro's CD10X212B-5 is intentionally designed for composite wood decks but may not be compatible with a softwood deck.

8. Strength Of Adhesion

Since the structural integrity of your deck largely depends on how well the planks are connected between themselves, the strength of your deck screws in terms of adhesion is worth considering.

The strength depends on a variety of aspects that each screw of a particular product embodies. These include the raw material used in production, drive type, build of the shank, thread count, etc.

For example, screws with reinforced necks/shanks will have superior "strength of adhesion". Screws made from heat-treated stainless steel will be stronger than copper or other metal screws.

Frequently Asked Questions

1. What is the Difference Between Self-Drilling And Self-Tapping Deck Screws?

Answer: A self-drilling deck screw doesn't require you to make any pre-drilling holes before using them. As you drive a self-drilling screw into the deck plank, it's designed to create its drilling hole through the process.

On the other hand, a self-tapping deck screw requires you to make a pre-drilling hole before usage.

However, they create less dust and debris during installation and provide more torque and driving power than regular deck screws.

2. What Kind Of Screws For Pressure Treated Wood Should I Use?

Answer: Pressure treated wood planks are stronger and provide better protection against erosion, infestation, dampening, and other quality degrading issues compared to untreated wooden planks.

However, due to their strong structural integrity and containment of various preservative chemicals, you'll need special types of screws for treated woods (which we’ve featured in this guide).

If you use regular screws with pressure treated wood, they may bend or slip and can become corroded by the preservative chemicals contained in the wood.

Thus, we recommend using 305 or 18-8 grade stainless steel screws with an advanced anti-corrosive coating, like the Hillman Fasteners' DeckPlus 48419 screws.

3. What is the Difference Between Screws for Treated Lumber And Screws For Pressure Treated Wood?

Answer: Practically speaking, there isn't much of a difference. Treated wood, lumber, planks, pressure treated wood, etc. are used as interchangeable terms in the industry.

However, technically speaking, treated lumber can mean any technique or technology that has been used to treat and upgrade a certain type of wood.

But pressure treated wood means, a specific technology, known as "pressure treatment" has been used to treat a particular batch of wood planks.

The technology uses a vacuum chamber to empty air pockets from a wooden plank, then floods the chamber with preservatives that are soaked into the plank.

4. Why is the Drive System Of A Deck Screw Important?

Answer: The drive system of the deck screw largely determines the ease of installation.

For example, screws that use a Torx drive (e.g. T25) or a Robertson drive (e.g. #2 Robertson Drive) will provide increased driving power and torque compared to screws that use a Philips drive system.

A Torx or Robertson drive will also lessen stripping, splitting, and cam-out issues compared to older drive systems.

5. What Is A Self Countersinking Deck Screw?

Answer: A self-countersinking screw is designed with usually a flat head and countersinking nibs. These features automatically level the screw-head with the ground of the deck. Thus, you can install/repair a deck without distorting the texture of its surface.

6. What Is The “Holding Power” Of A Deck Screw?

Answer: The "holding power" of a screw, also known as "ground adherence", simply means how well a screw can connect or keep together different deck planks or lumbers.

Screws with higher holding power will have better tensile strength. They can increase the internal structural integrity of a deck better than screws with lower holding power or nails.

Final Word

Deck screws come in a variety of shapes and forms. Also, there are nuances involved in its anatomy that can be tricky to understand and critique.

We've covered compatible deck screws for all types of deck woods (e.g. natural wood, artificial wood, treated wood, etc.) in this guide.

However, choosing the best deck screws for pressure treated wood or lumber decks can be especially difficult, as buying factors increase in this situation. That’s why we’ve emphasized this issue and covered it in depth.

We hope this guide will be a "one-stop for all" solution for you when it comes to buying deck screws.

Our Other Related Resources:

Our Selected Deck Paint For Old Wood

- How to Choose Wood Filament: A Complete Guide - July 17, 2021

- 10 Best Propane Forge Reviews - June 30, 2021

- Best Circular Saw Blade for Plywood : Top 10 Picks - June 30, 2021